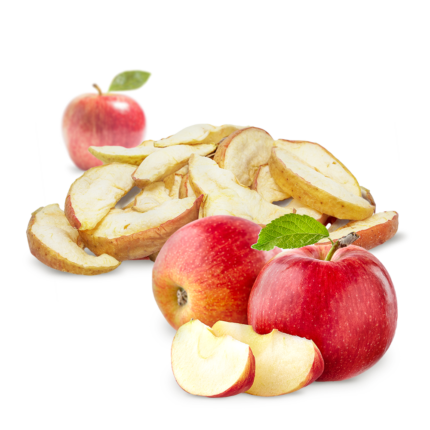

A unique drying technology that brings extraordinary results in an exceptionally short time and low (but, most importantly, positive) temperature of, among others, fruit and vegetables. It allows a very high level of nutritional value in the final product to be maintained. Dried products regain their natural texture, taste and smell in the rehydration process, depending on the raw materials used.

MIRVAC®

The best methods of drying natural food ingredients

Main advantages

- stable final product structure

- wide range of shapes and fractions

- microbiologically clean products

- low bulk density of dried fruit and vegetables

- adaptation to individual customer needs

- unique technology on global scale

Experience and knowledge

From the very beginning, when the idea for MIRVAC® technology was born, we set ourselves the goal of developing a drying method that would transform traditional products into even better ones – the ones that consumers expect in the finished products of our partners.

SAFE

Microbiologically clean water, thanks to the use of a vacuum in the drying technology, boils as low as at 20’C, which makes it possible to effectively eliminate microorganisms.

CONTROLLED

Verified for years by experience and numerous audits. Controlled at every stage of production, from the raw material to the final goods.

MODERN

The drying process is the shortest from those applied on the industrial scale – it takes only 2-3 hours. It allows healthy products to be obtained, of high quality and very good flavour.

INNOVATIVE

UNIQUE

As compared to the freeze drying technology, the more advanced and modern MIRVAC® technology allows you to get: better taste, appearance, texture, crispness and natural & long-lasting colour corresponding to fresh fruit or vegetables.

EFFECTIVE

It allows very high levels of ingredients and the nutrients (e.g. fibre) to be maintained.

FUNCTIONAL

USED ALL OVER THE WORLD

Used by clients in 36 countries worldwide, enjoying great popularity and recognized due to its advantages.

EXAMINED AT MANY STAGES

Starting from a time of strict quality inspections of the raw material, also in the scope of pesticides, and at the end of the process, for conformity to even more detailed parameters. The tests are conducted in our internal, modern laboratories and in independent, accredited laboratories.

Need some inspiration?

You can always rely on our experience and creative approach. Send us an email to info@PAULAingredients.com or fill in the contact form today.

The method consists of enriching the final product with high-quality functional ingredients (such as fibre, inulin, vitamins, concentrated juices or honey) to give it specific properties and increase its nutritional value.

Thanks to this, the finished products have a diverse form, crispiness and texture, can be tailored to the individual needs of our customers while having a wide range of applications.